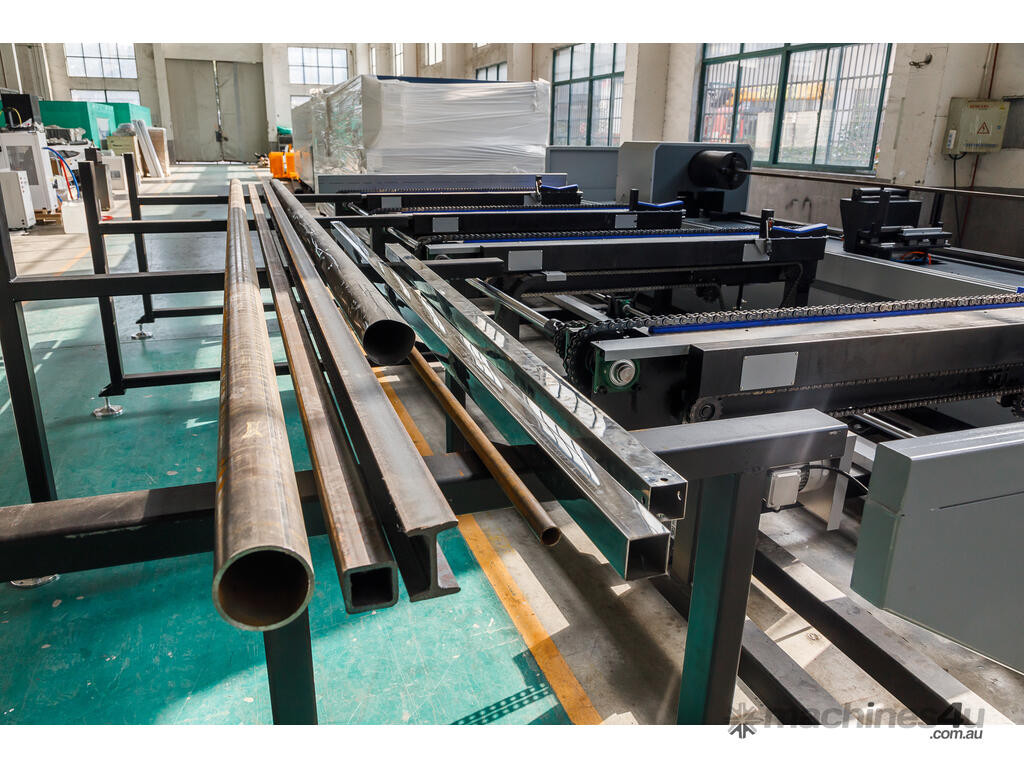

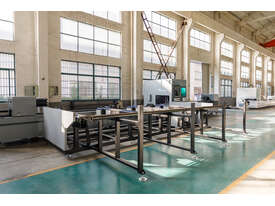

ACCURL TubeLINE A SERIES 3KW | 6.5M LENGTH | 240MM OD TUBE LASER | BOCI HEAD | CYPCUT CONTROLLER

Confirm if additional costs apply

-

-

-

-

+37

+37

ACCURL TubeLINE A SERIES 3KW | 6.5M LENGTH | 240MM OD TUBE LASER | BOCI HEAD | CYPCUT CONTROLLER : $138,000 AUD ($151,800 Inc. GST)

Confirm if additional costs apply

The Accurl tube lasers are a step ahead of their competitors being a machine that's been produced and constantly improved upon by Accurl for a number of year, Accurl sheet metal machinery offer high level technology machinery within its market segment and is a progressive forward thinking company constantly improving their products and product range. Its because of this Complete Machine Tools has taken on the agency for Accurl machines in Australia. Why limit yourself to a company that only can supply a laser cutting machine, go with a company who can grow with your business and offer a complete solution for all your sheet metal and fabrication machinery needs under the 1 roof.

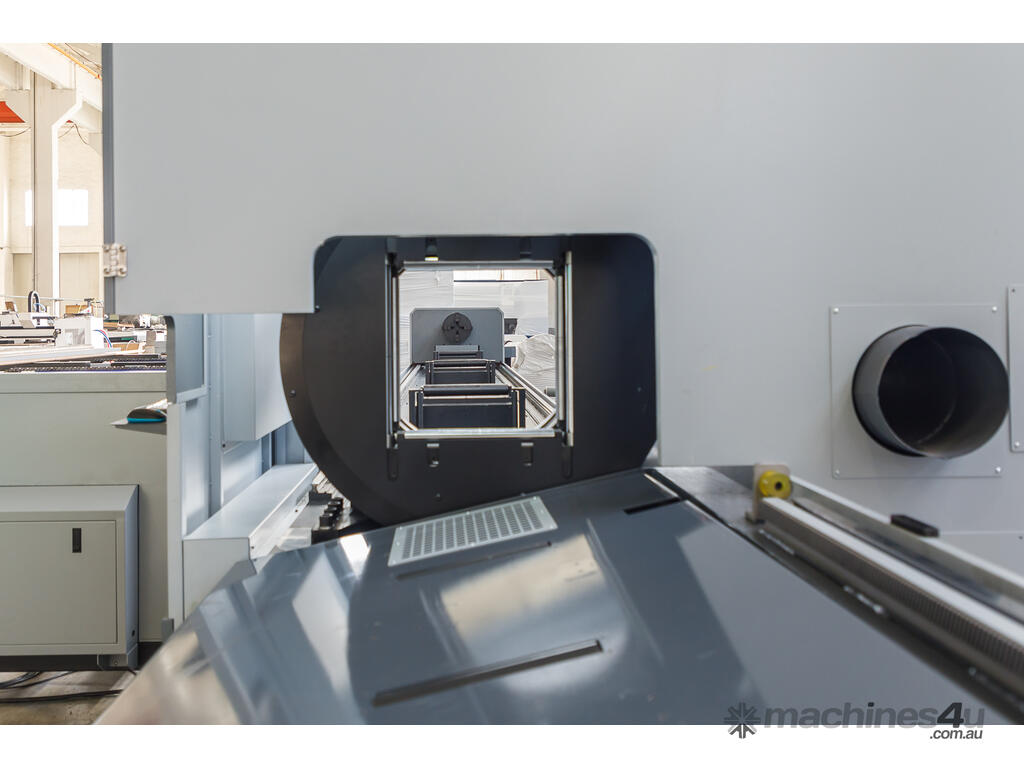

TUBELINE SERIES

TUBE LASER CUTTING MACHINE

ACCURL makes tube manufacturing more efficient

and cost-effective with laser cutting technology. Using a

single, flexible tool, a variety of tube shapes can be

processed – with high cut quality and accuracy that

simplifies or eliminates secondary processes.

With class leading features in its segment Accurl offers a great quality machine at a competitive price.

The TubeLINE A Series is the simplest way to enter the tube laser cutting world

STANDARD & OPTIONAL FEATURES AND SPECS -

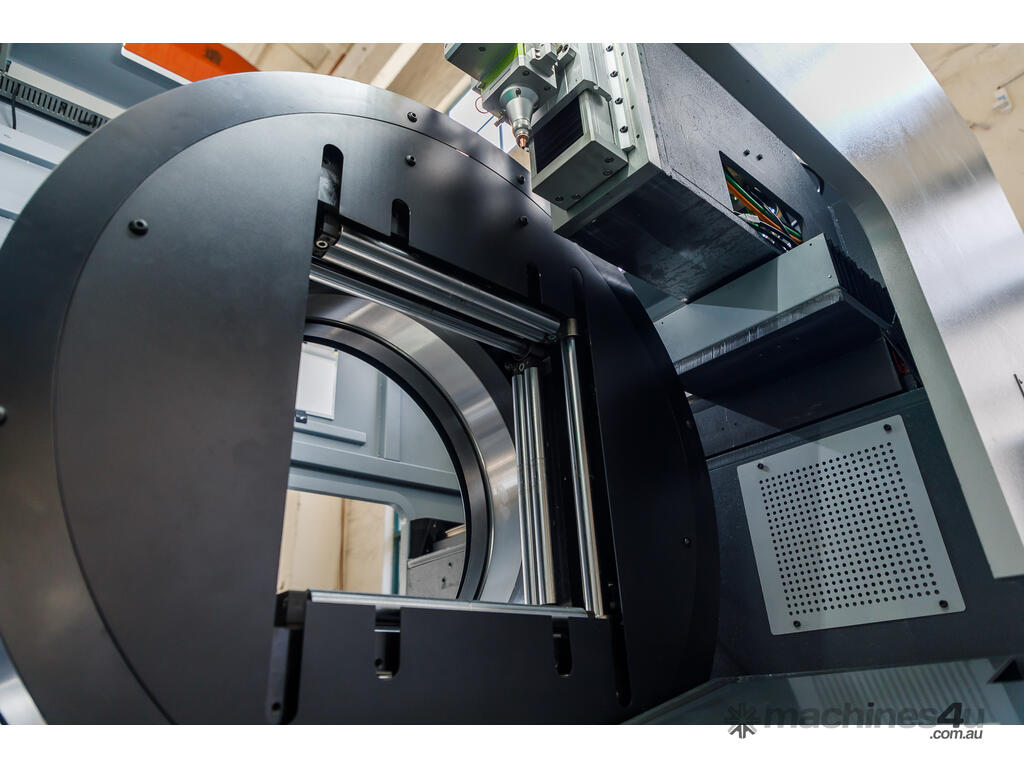

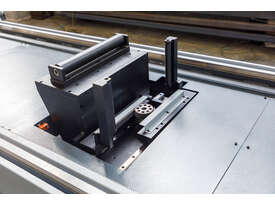

Laser Cutting Head: ACCURL BLT Series (Auto Focus)

Laser Sources: IPG & MAX Photonics

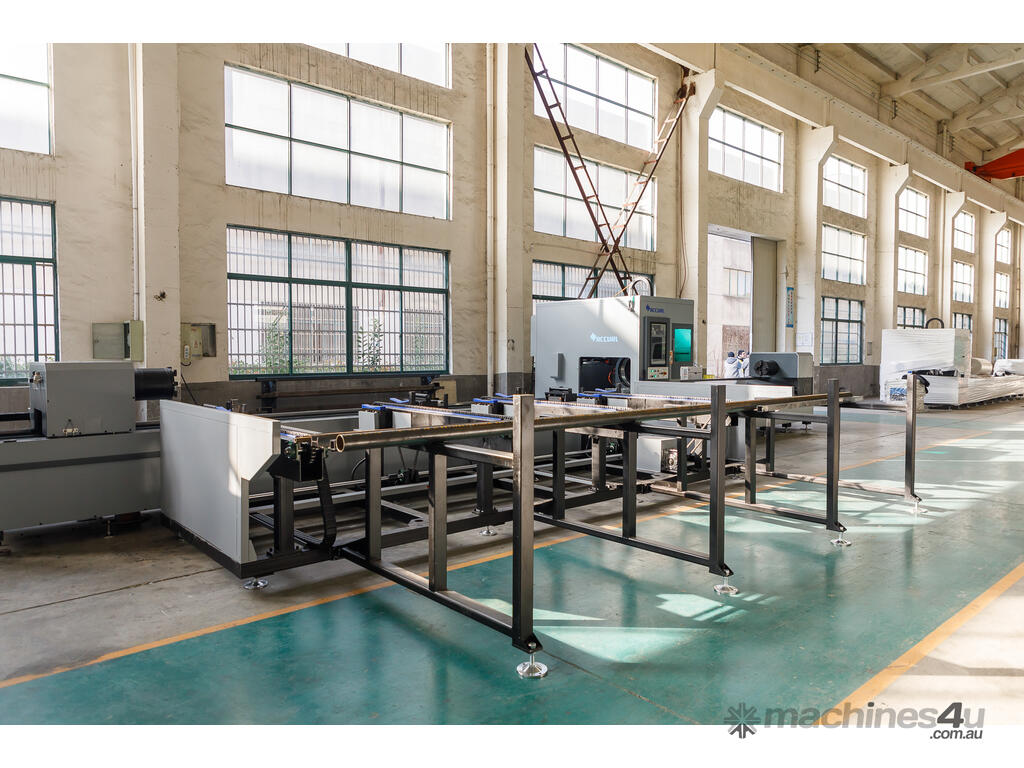

For LoadMaster Tube: 6M / 7m / 9m / 12m (Optional)

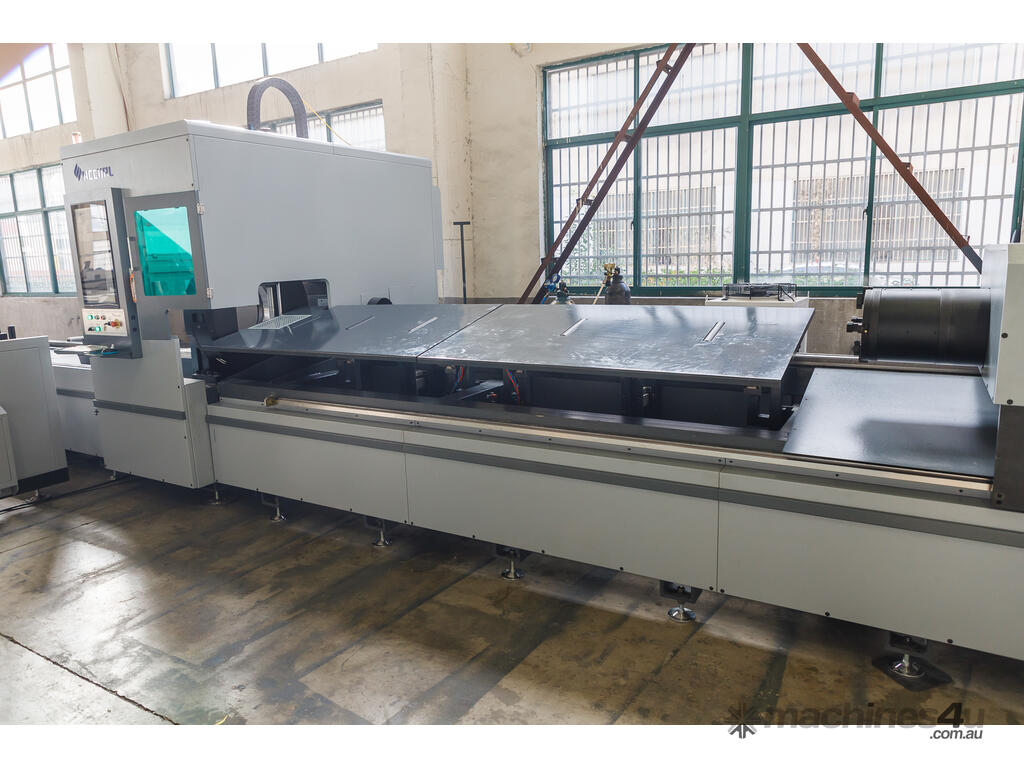

Maximum Tube Length & Weight: 12000mm, 1200kg

(Sizes - 6 | 7 | 9 & 12m tables lengths available)

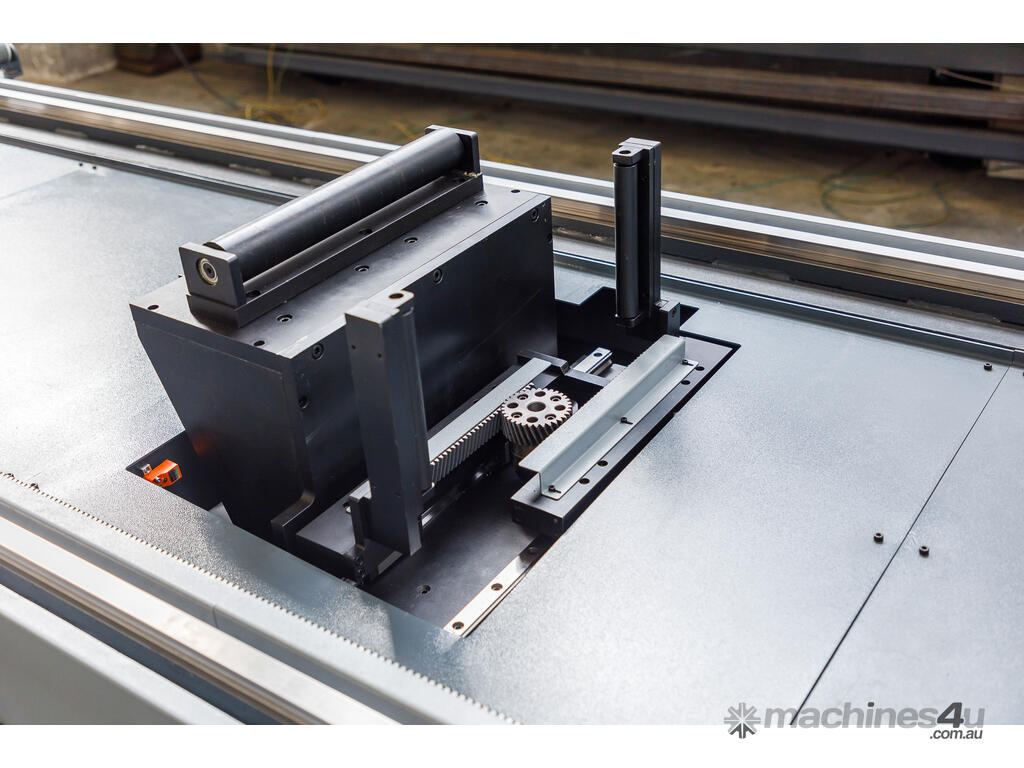

Motion System: Yaskawa Servos & Drivers - X,Y,Z Axis

X.Y.Z axis position accuracy: ±0.02mm

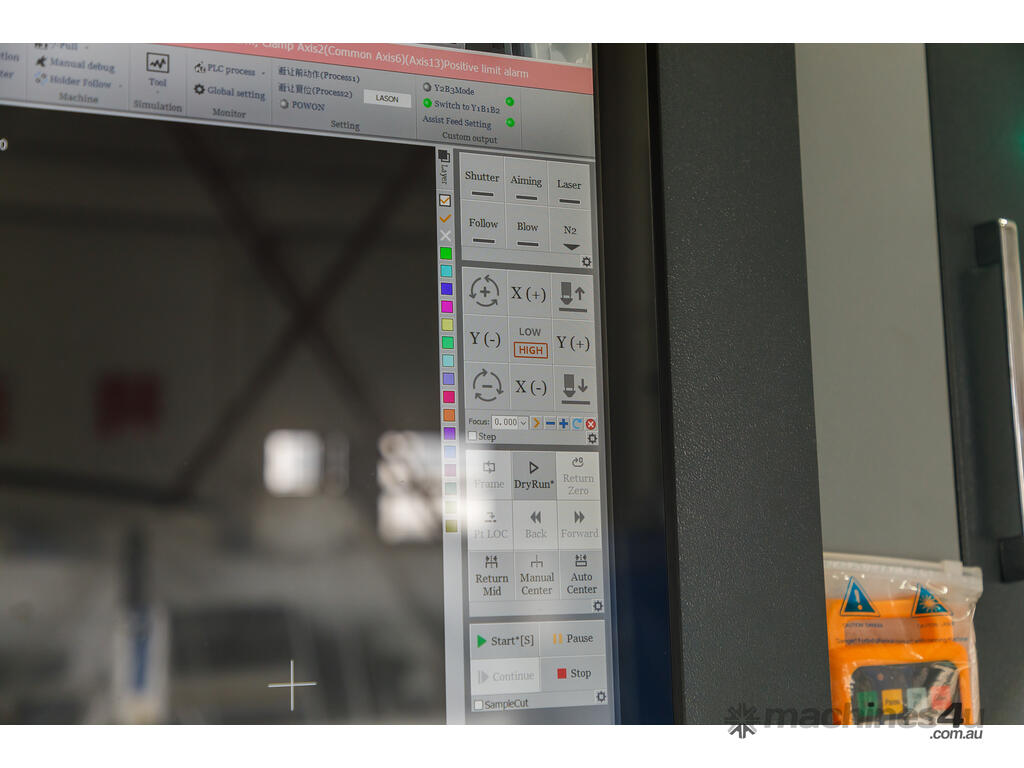

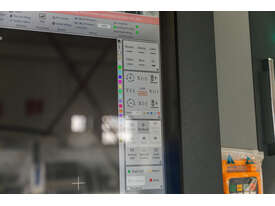

User Interface (HMl)?ACCURL 21.5”Touch Screen with Camera Display

Fume Extraction - Dust Collector (Optional)

Class IV safety system and CE marking

- 1kw to 12kw power sources available

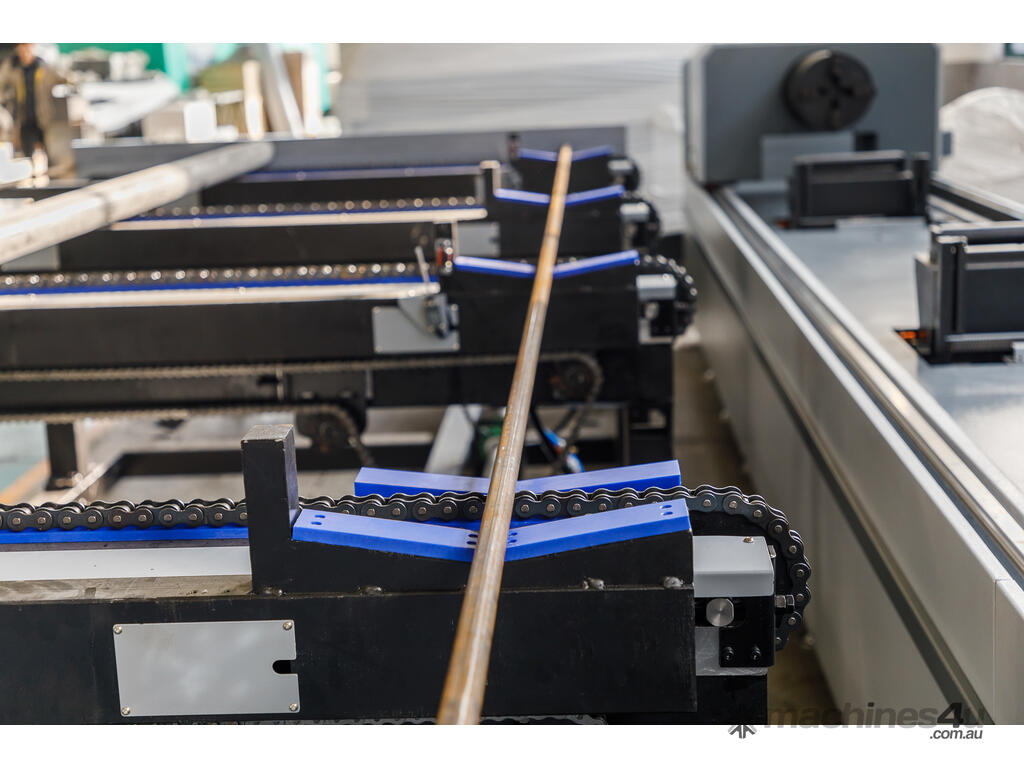

- Available with an auto loading system

- 220 | 280 | 310 | 360 mm capacities available

- Available in left hand or right hand configurations

- Extended check claws for minimal remnant pieces

-- Outfeed support table

- Automatic detection of the material centre and edge

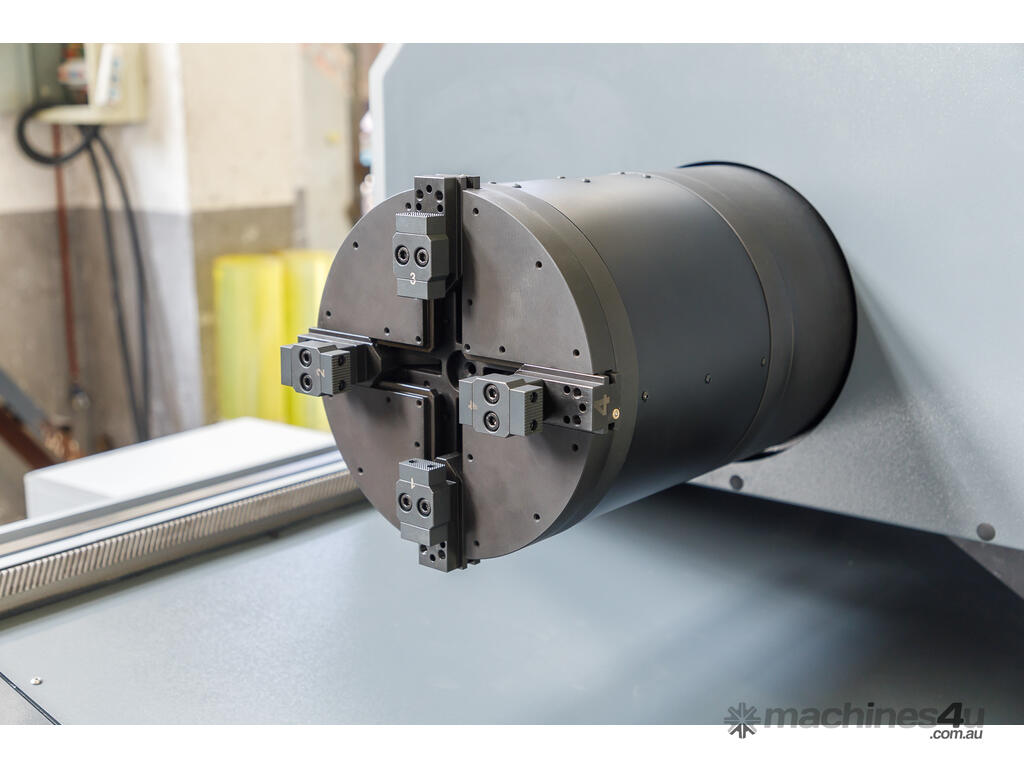

- Integrated chuck in the machine body for extra rigidity and long term accuracy

- Optional seam weld detection

Max no load running speed - 100m/min

Max no load turning speed - 100r/min

**BEVEL HEAD AVAILABLE**

Custom machines are available so if there is a specific requirement please contact us to discuss

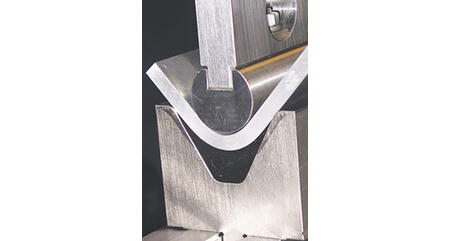

NB - Some pics shown are shown with optional items fitted

Confirm if additional costs apply

New PUMA HNM-6 NOTCHER | 6MM CAPACITY | FIXED ANGLE | HYDRAULIC

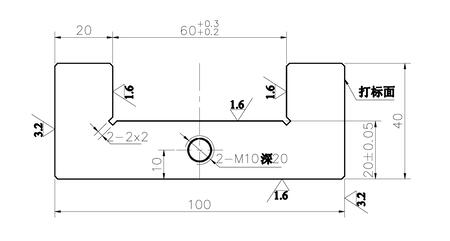

New MANUALLY ADJUSTABLE CROWNING BOTTOM PRESS BRAKE TABLE | 4000MM LENGTH | 240MM WIDE

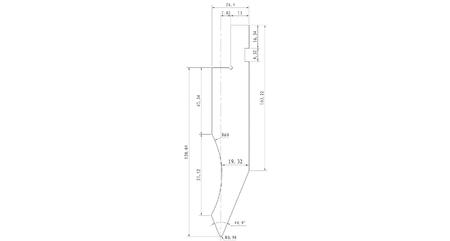

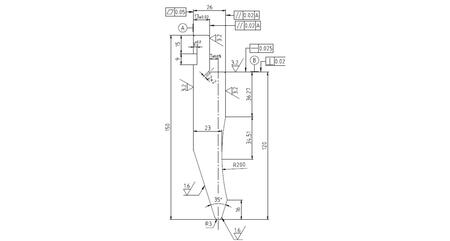

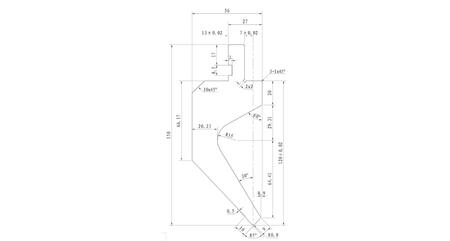

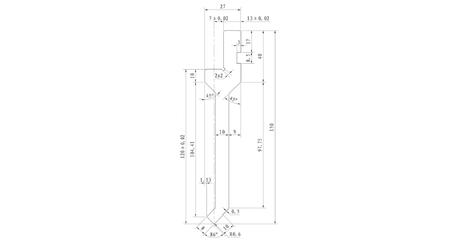

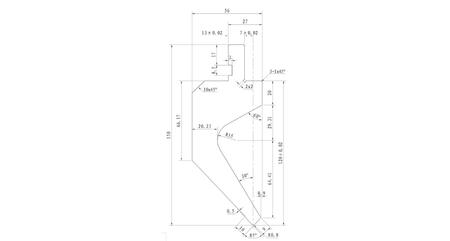

New 45 DEG / R1MM PRESS BRAKE TOOLING TOP PUNCH | EURO TYPE

New 35 DEG / R1MM SEGMENTED PRESS BRAKE TOOLING TOP PUNCH | EURO TYPE

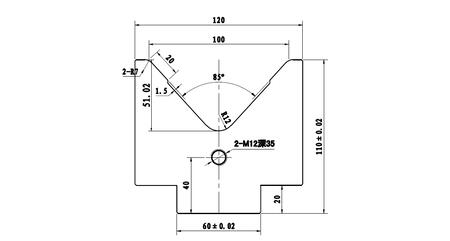

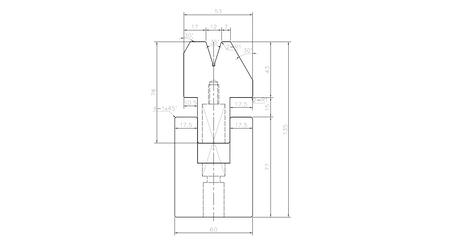

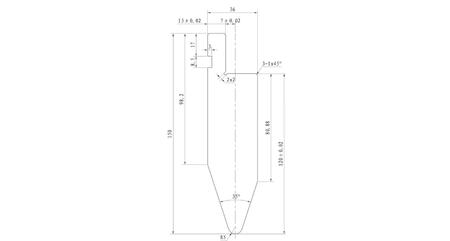

New 100MM V / 85 DEGREE SINGLE V BOTTOM PRESS BRAKE TOOL | TO SUIT 60MM BASE

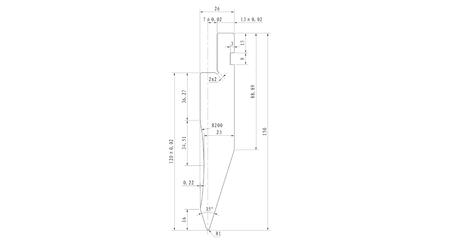

New 35 DEG / R3MM PRESS BRAKE TOOLING TOP PUNCH | EURO TYPE

New 85 DEG / R0.8MM GOOSENECK PRESS BRAKE TOOLING

New FLATTENING COMBINATION BOTTOM PRESS BRAKE TOOLING | 12MM V OPENING | SPRING LOADED

New 35 DEG / R1MM PRESS BRAKE TOOLING TOP PUNCH | EURO TYPE

New 86 DEG / R0.6MM OFFSET PRESS BRAKE TOOLING TOP PUNCH | EURO TYPE

New RADIUS BARS | 8 - 60MM DIAMETER KEPT IN STOCK

New 85 DEG / R0.8MM GOOSENECK SEGMENTED PRESS BRAKE TOOLING

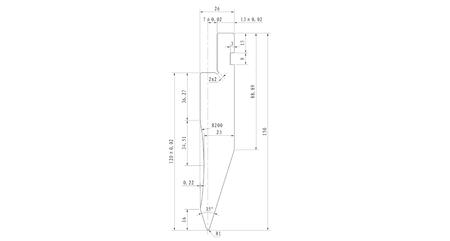

New 35 DEG / R5MM BULL NOSE PRESS BRAKE TOP PUNCH | EURO STYLE

New BOTTOM 4000MM PRESS BRAKE DIE RAIL TO SUIT 60MM DIE

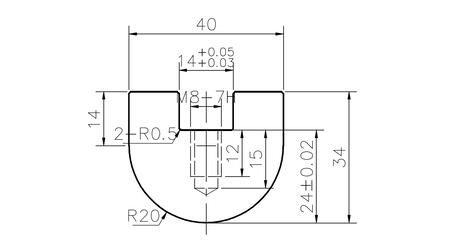

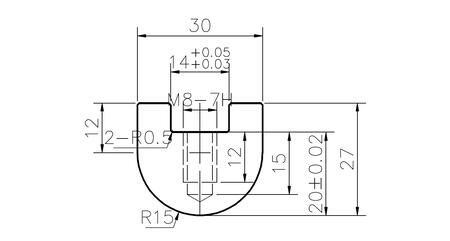

New R20mm RADIUS BAR PRESS BRAKE TOOLING | TO SUIT LARGE RADIUS BAR HOLDER

New R15mm RADIUS BAR PRESS BRAKE TOOLING | TO SUIT LARGE RADIUS BAR HOLDER

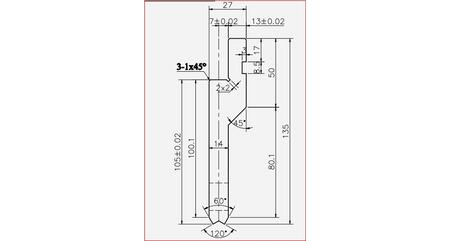

New PRESS BRAKE RADIUS BAR HOLDER TO ACCOMDATE BARS UP TO 20MM DIA | EURO STYLE

New PUMA HNM-6A | 6MM VARIABLE ANGLE NOTCHER & PUNCH | DUAL STATION

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print