IMET CUBO 350 NC BOX BANDSAW | SINGLE MITRE | FULLY AUTO | 350MM x 200MM (ITALIAN MADE)

IMET CUBO 350 NC BOX BANDSAW | SINGLE MITRE | FULLY AUTO | 350MM x 200MM (ITALIAN MADE) : $43,000 AUD ($47,300 Inc. GST)

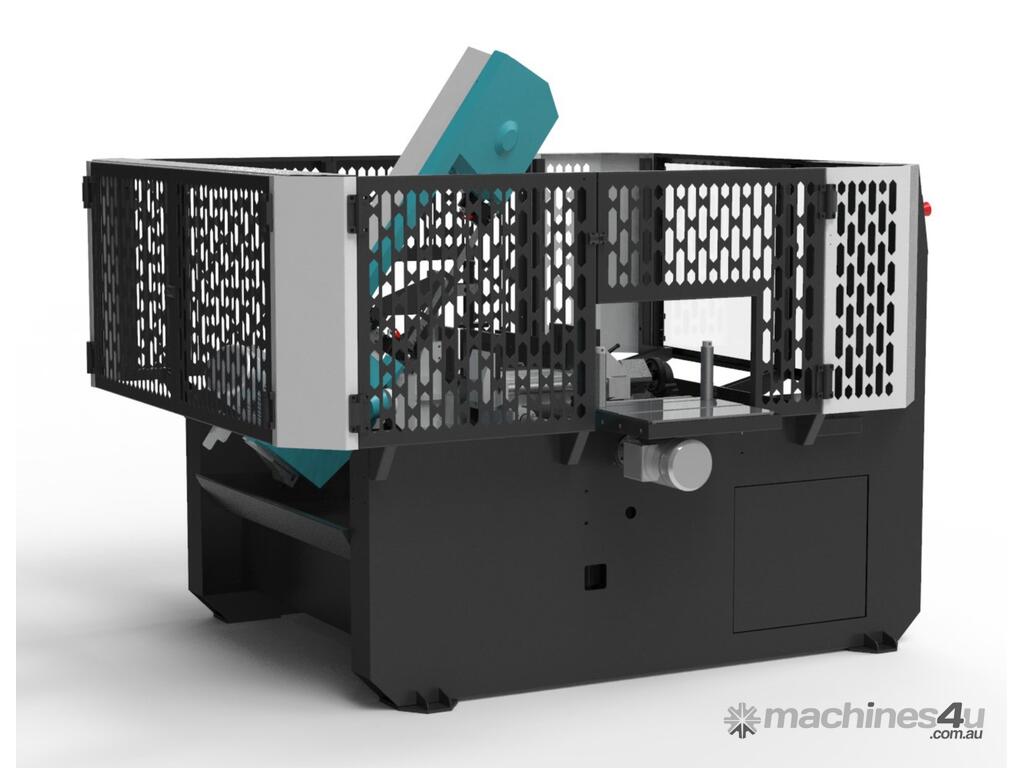

The IMET CUBO NC box is a numerical control automatic sawing machine that's manufactured in Italy.

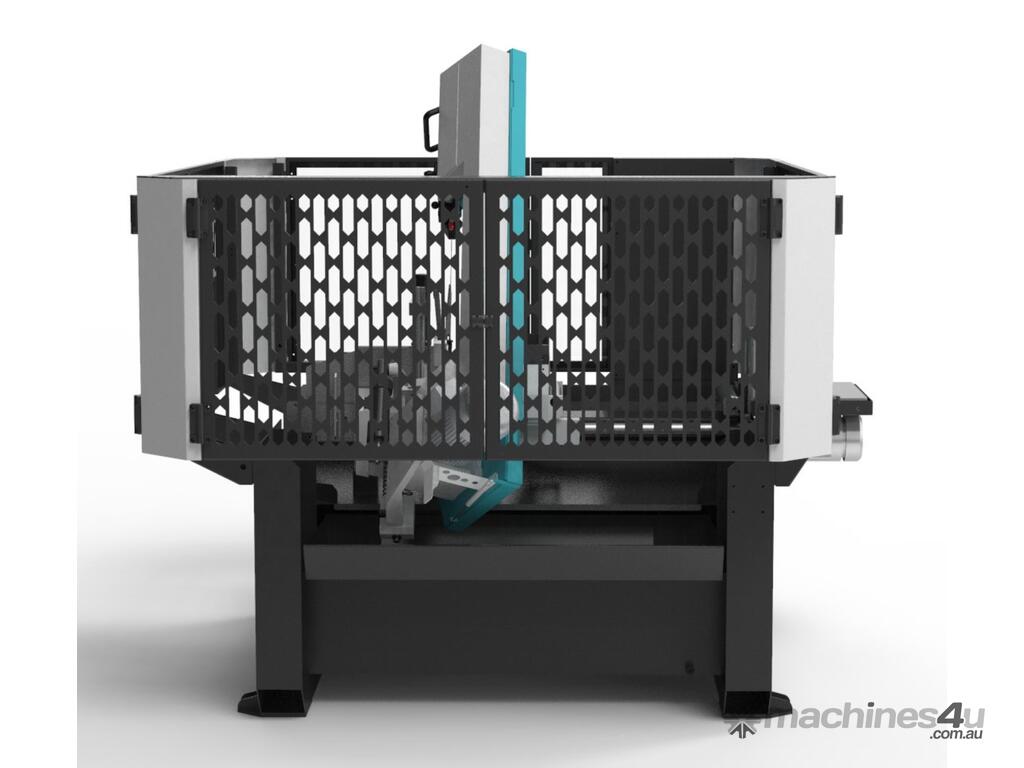

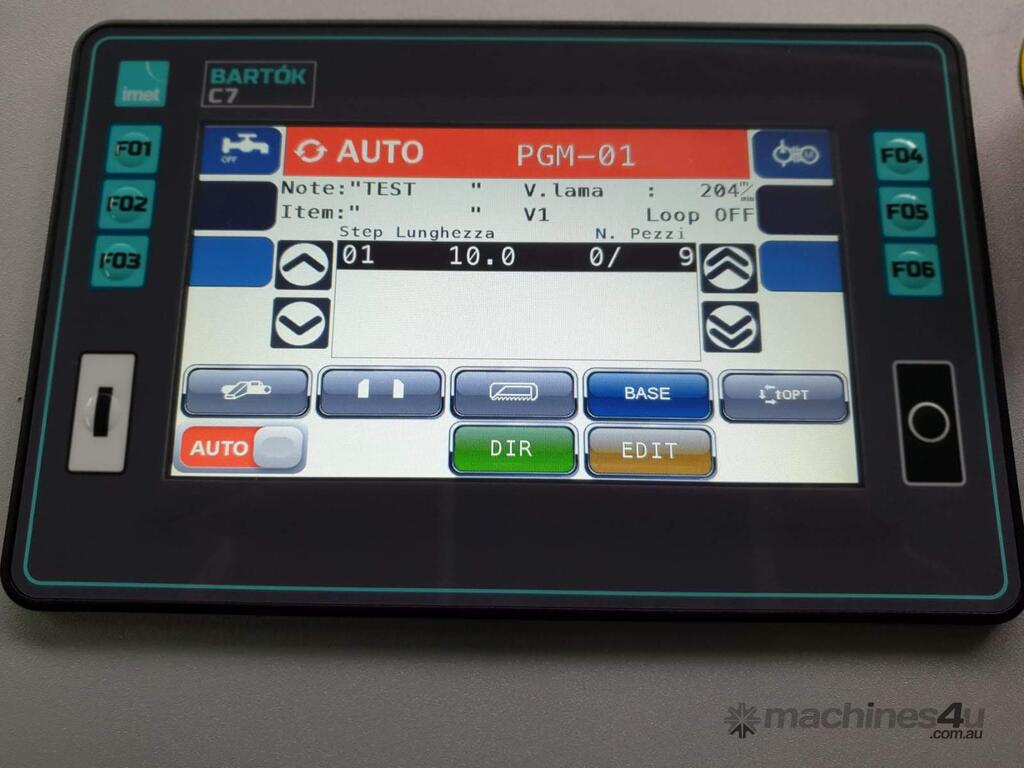

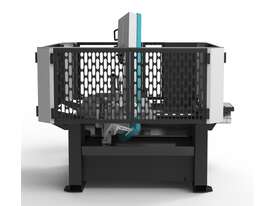

CUBO 350 NC BOX is an automatic sawing machine belonging to the innovative CUBO SERIES. It is a reliable, safe and easy to use work tool thanks to the 7 "touch screen display with the possibility of remote cutting management via INDUSTRY 4.0 READY. The rotation of the bow is manual with integrated feeder carriage and can be optioned up with automatic bow rotation.

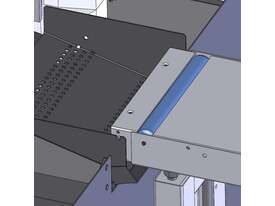

• Model CUBO 400 NC is a forefront bandsaw that provides safety to the user by protecting all the 4 sides with special design metal sheets that covers all the moving part of the bandsaw. The protection system allows full accessibility for maintenance.

• Innovative and easy to use 7” touch screen display with intuitive interface to have control on all the machine settings. It’s possible to program up 99 cutting programs and 10 different cutting length on the same bar.

• CNC control gives access to all the machine operative functions: automatic calculation of the blade thickness, number of stroke repetitions, blade speed and lowering feed rate. The interface also allows to view CUBO status while working and anomalies with self-diagnosis.

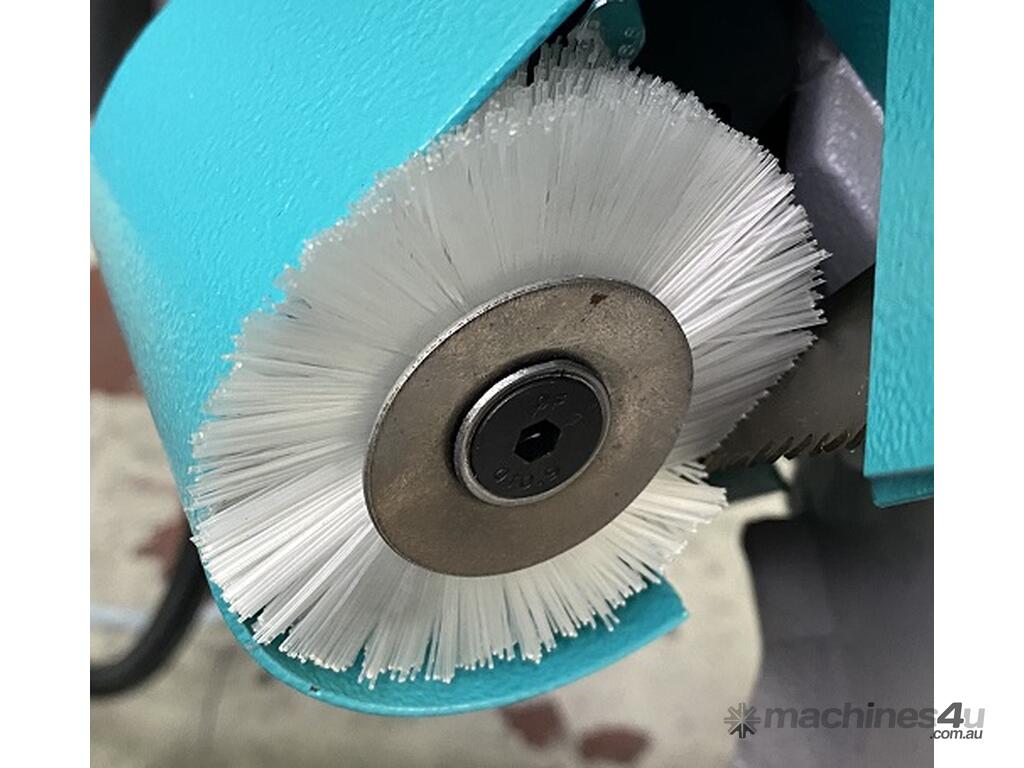

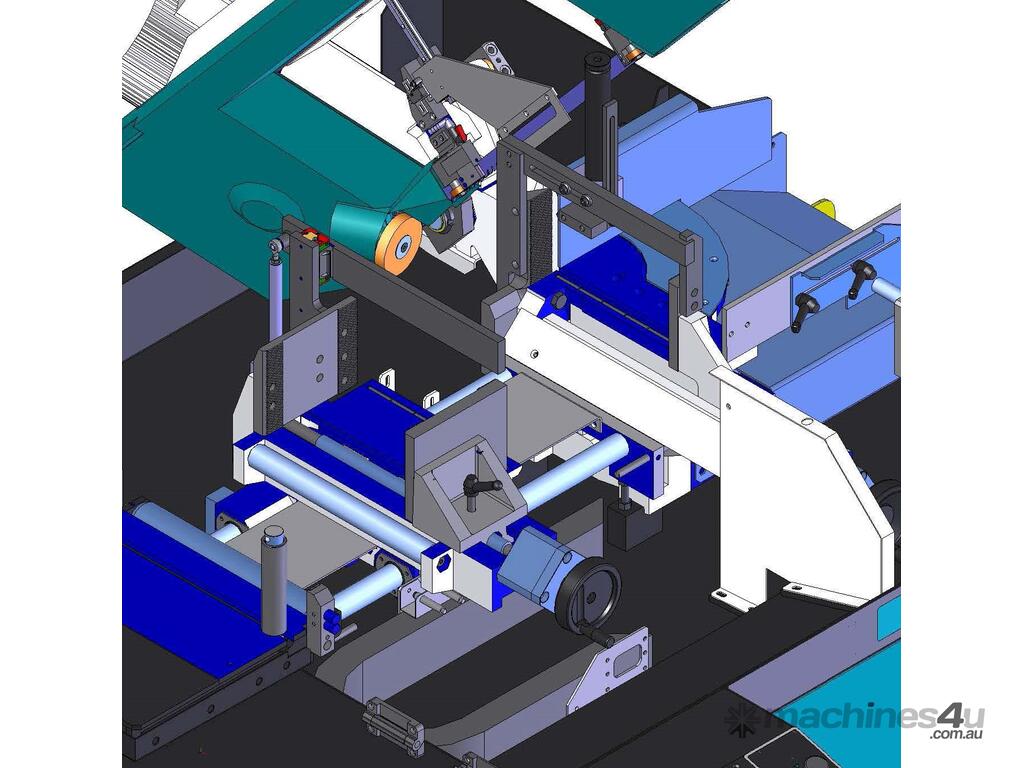

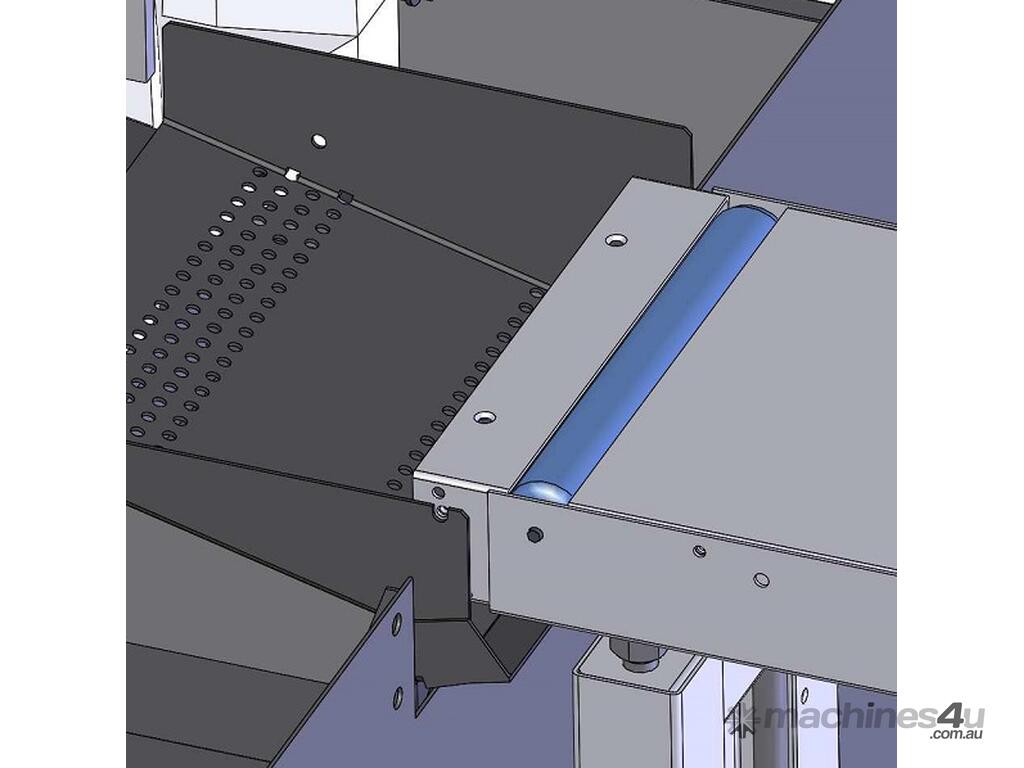

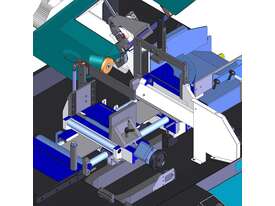

• Integrated feeder for automatic repetition of the cutting process. The feeder slides on hardened and chromed bar; high positioning precision due to the incremental feeding on recirculating ballscrew by self-braking electric motor with inverter, mounted on floating plate to ease the loading of non-rectilinear bars.

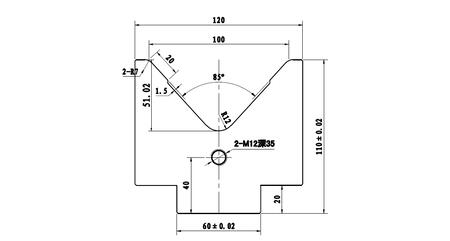

• The sawframe has rigid, cast-iron, IMET produced structure with tubular section that provides high resistance to strain and better performances on every sections and material. Bow is equipped with cemented and hardened endless screw and crown made in high resistance bronze alloy.

• The material mechanical detect device provides for fast blade approach to the material, automatically detecting the first cut point while the end cut is managed with a microswitch on the mobile blade guide, which allows to have perfect blade alignment thanks to the hard metal pads and supplementary bearings

IMechanical feeler device

CUBO 350 NC BOX is equipped with a mechanical device for the automatic detection of the material and the cutting start point, optimizing the cutting process. The management of the end of the cut is instead guaranteed by an adjustable control microswitch

Advance carriage

The feed carriage has a maximum stroke of 515mm. The feeder movements is on chromed bars with high positioning accuracy due to the incremental feeding on recirculating ball screw by self-braking electric motor with inverter.

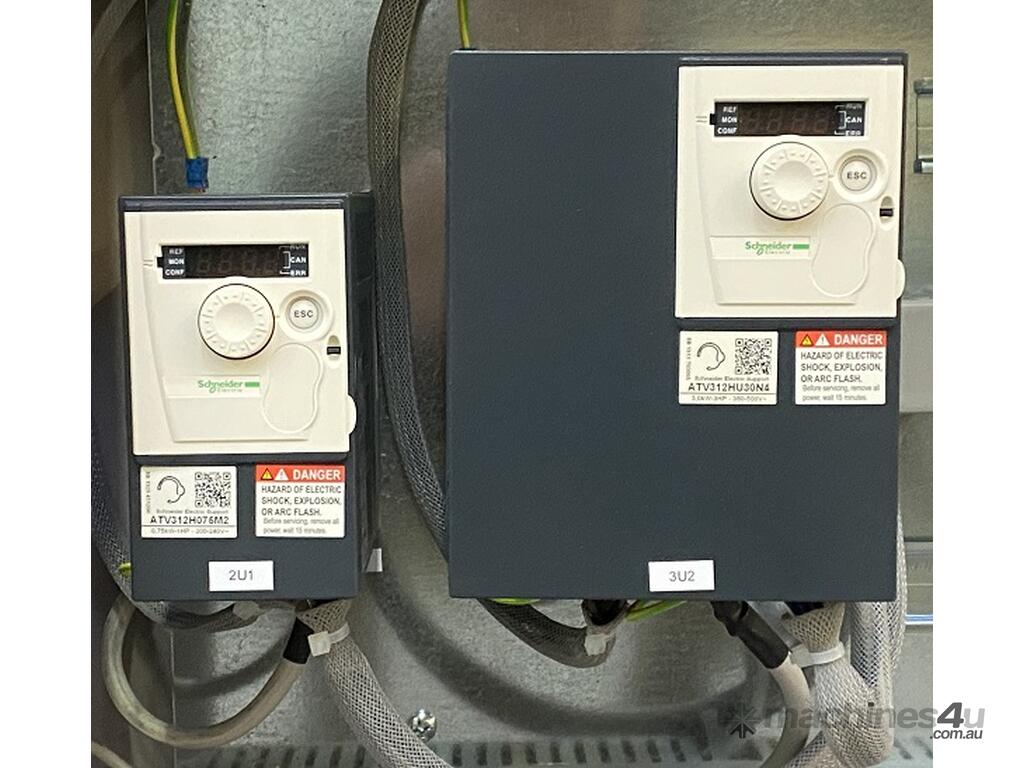

Speed variator

All CUBO SERIES automatic saws (in the BOX and FLAT versions) are equipped as standard with an inverter blade speed variator.

Automatic sawframe rotation (Optional)

CUBO 350 NC (Flat and Box) are compatible with the automatic sawframe rotation device. The system has mechanical stops with 2 positions and allows to optimize user workflow with mitre cutting on a same bare in automatic cycle.

Link: youtu.be/wZAjSwt6x3Y

industry 4.0 ready - SAWFACTORY (Optional)

All CUBO Series automatic saws can be connected to the company network via modem: the dedicated software SAWFACTORY is also available for remote service, assistance, programming and remote management of the cutting process. The software allows to transfer data and programs from the PC (where the program is created) to the machine via USB. Discover SAWFACTORY:

bit.ly/2RuxHuX

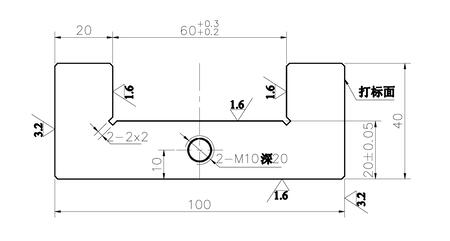

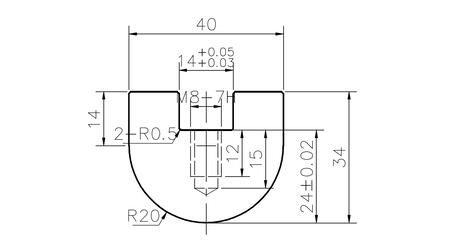

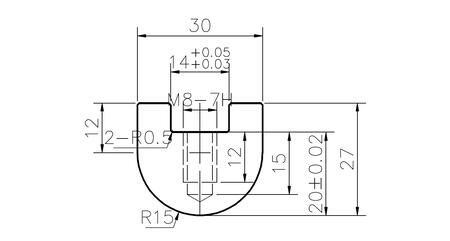

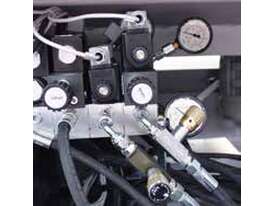

Hydraulic device for bundle cutting(Optional)

The CUBO automatic band saws in the BOX version can be used with the bundle cutting device. The bundle cut can only be used for 0° cutting. Single piece capacity with mounted device: 350x160mm max, 55x10mm min. Cutting capacity for bundle is: max 300x160mm, minimum 85x10mm. The device can be disassembled using the 2 screws on the fixed vice and the 2 on the carriage vice and disconnecting the hydraulic tubes using the quick couplings systems.

TECHNICAL INFORMATION

Cutting capacity at 0 °

Round: 305mm

Square: 250mm

Rectangle: 350x200mm

Cutting capacity at 45 ° left

Round: 255mm

Square: 230mm

Rectangle: 230x200mm0mm

Cutting capacity at 60 ° right

Round: 175mm

Square: 155mm

Rectangle: 170x100mm0mm

Bundle cutting capacity Max: 300x160mm; Min. 90x10mm

Cutting capacity at 0 ° full (C45)) 200mm

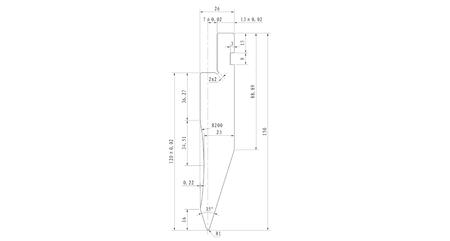

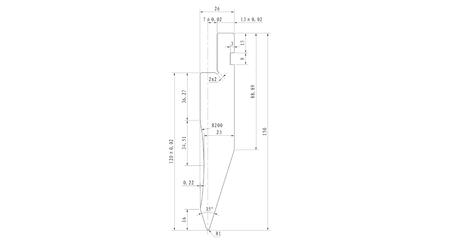

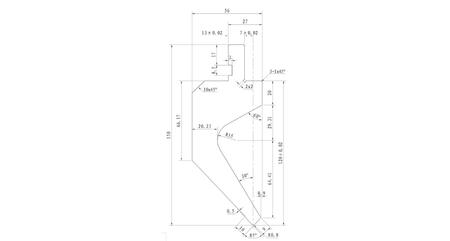

Blade size 3370x27x0.9mm

Blade motor 1.8KW

Blade speed 15-100 m/min

Stroke of the feeder carriage (repeatable)

Motor of the feeder carriage 0.75KW

Minimal scrap end 80mm

Hydraulic power unit tank capacity 20l

Coolant tank capacity 100l

Minimum length that can be cut 15mm

Maximum cuttable length 9999mm

Dimensions 2200x2385x1610mm

Weight 950kg

Height of the work surface 880mm

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print